Plasma powder spheroidization system – TEKSPHERO-15

TEKSPHERO-15 was acquired at the end of 2023 for the spheroidization of powders for reactive metals because it is the ideal solution for the development of new spherical powders

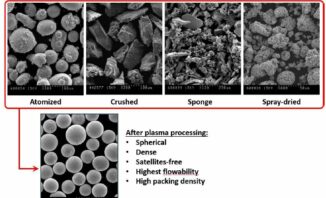

It allows the transformation of either agglomerated powders produced by spray drying or sintering techniques, or angular powders produced by conventional crushing methods, into spherical powder. Powder densification and spheroidization is a widely accepted application of induction plasma technology. It essentially involves the in-flight heating and melting of the raw material, followed by its subsequent cooling and solidification under controlled conditions.

Depending on the size and bulk density of the processed powder, their flight time is controlled such that the molten droplets have sufficient time to completely solidify before reaching the bottom of the primary reactor chamber. The finer particles, entrained by the plasma gases, are recovered in a filter downstream of the primary chamber. Densification and spheroidization of powders will provide the following benefits to users:

The process results in considerable improvement in powder properties in multiple aspects:

- Improved powder flow properties => Spheroidized particles provide a more consistent and stable flow during feeding. This allows streams to run at faster or slower rates without clogging issues.

- Reduction in powder porosity => The porosity disappears when the material melts. This results in a better material for use in powder metallurgy applications and denser coatings.

- Increased Powder Density => The tapped density of the powder is increased due to the presence of spherical and dense particles, resulting in a denser coating or parts.

- Decreased powder friability => Wear of parts and coatings can be reduced by reducing edges, crumbling, flaking or fragmentation of the powder used before processing. The treatment eliminates internal fractures or weak internal bonds and ultimately results in a longer lifespan for coated parts.

- Improved powder purity => The in-flight melting process can also be used advantageously to improve the purity of the initial material by a factor of 10 to 100. The powder contaminant can be brought down to ppm or ppb levels in one or more passages depending on the initial composition of the precursor.

- Elimination of satellites, hollow or fractured particles to limit wear on transport pipes and increase the quality of the products used. These high-quality metal powders are compatible with the most demanding industrial processes: Metal Injection Molding (MIM: Metal Injection Molding), Additive Manufacturing (AM: Additive Manufacturing), Thermal Spraying and Hot Isostatic Compression (HIP). : Hot Isostatic Pressing).

Versatile and scalable, the system makes it possible to develop the most sensitive metal powders or alloys (e.g.: Al and Ti) but also ceramics in a neutral or reactive atmosphere (Ar, N2, O2, H2, etc.) for sizes varying from 5 to more than 200 μm.