Assessing the corrosion resistance of implanted metal

Question

Can the corrosion resistance of noble metals be improved by ion implantation treatment? What are the most suitable treatment conditions? How can this improvement be quantified?

Expertise

Materia Nova has recognized expertise in the field of electrochemical techniques, particularly for assessing the corrosion resistance of metals.

Through the Walibeam project, Materia Nova and Ionics have developed and industrialized an innovative surface modification technology: ion beam implantation. The process enhances the mechanical properties and durability of metal surfaces. A specific study was carried out on various noble metals used in the connector industry, with the aim of significantly reducing the thicknesses of the metal deposited.

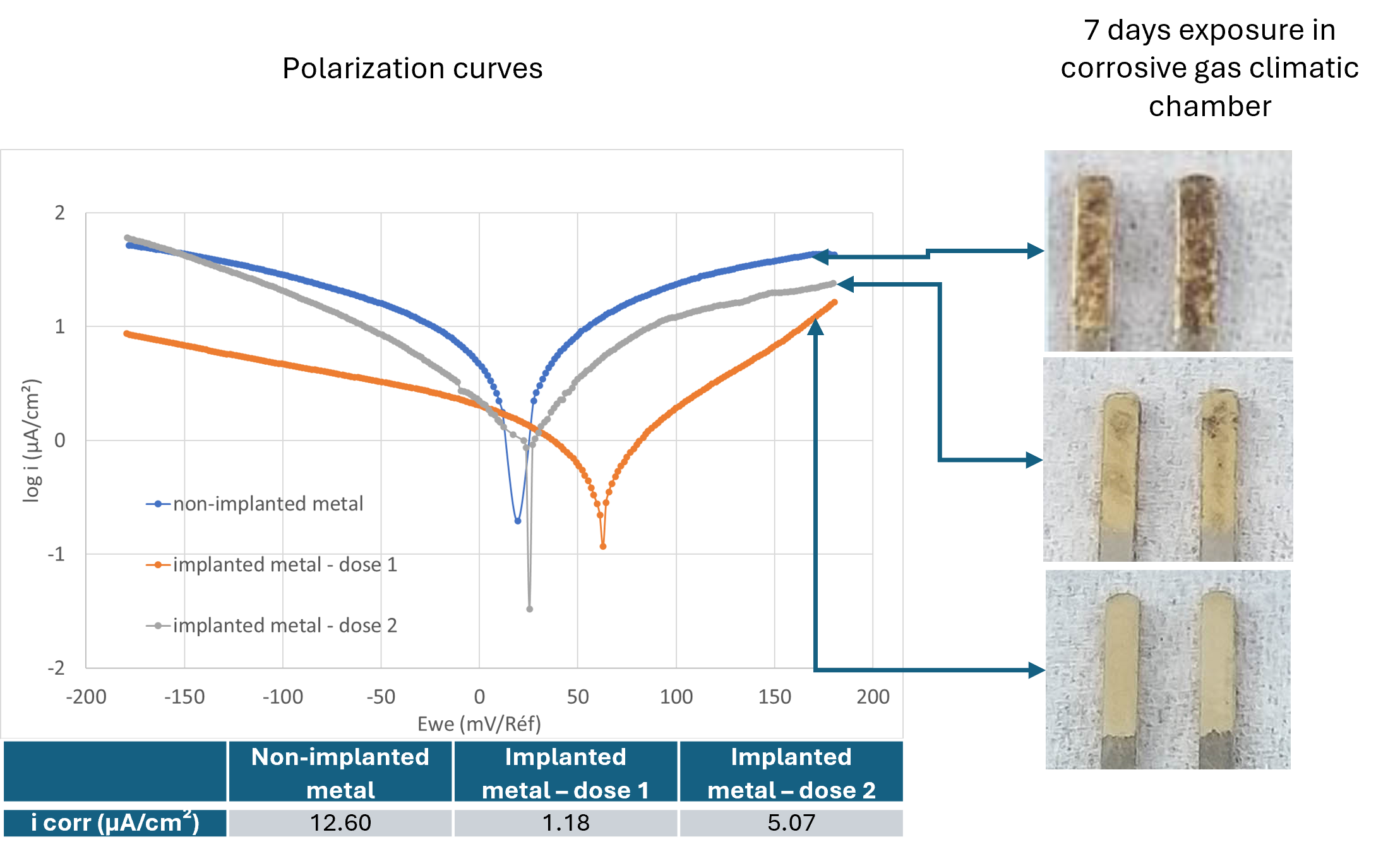

In this case study, an electrochemical method for quantitative measurement of corrosion resistance was used. The aim is to optimize the conditions for implanting thin gold layers electroplated on nickel-coated copper. By plotting potentiodynamic polarization curves, the corrosion current density of a metal can be determined quickly (±1h). The lower a metal's corrosion current density, the higher its corrosion resistance. In practice, samples are immersed in an electrolytic medium determined by the application. A potentiostat is used to sweep the voltage around the rest potential and record the system's current response.

By way of example, gold layers implanted with 2 different doses of ions (dose1 > dose 2) and not implanted are compared. The results of the electrochemical measurement are compared with a 7-day corrosive gas ageing test (Intl Standard IEC 60068-2-60).

The corrosion rate of metal implanted under conditions 1 is 4 times lower than under conditions 2, and 10 times lower than without implantation. In addition, the shift in corrosion potential towards more positive values indicates surface ennoblement.

Solution

Measurements of polarization curves and their correlation with a corrosive gas ageing test have enabled us to optimize the implantation parameters and highlight the significant increase in corrosion resistance of the implanted metal. The electrochemical technique makes it possible to discriminate between implant conditions.