PE/PP Composites with High Organic Waste Content

Question

Is it possible to incorporate up to 45 wt.% of household organic waste (rich in cellulose, notably from paper, cardboard, roots, and plant residues) into conventional polymers such as PE or PP, in order to produce composites capable of replacing conventional plastics while ensuring economic viability?

Expertise

Materia Nova has expertise in polymer chemistry, polymer processing by (reactive) extrusion, and materials analysis techniques. These three areas are essential for developing materials with controlled properties.

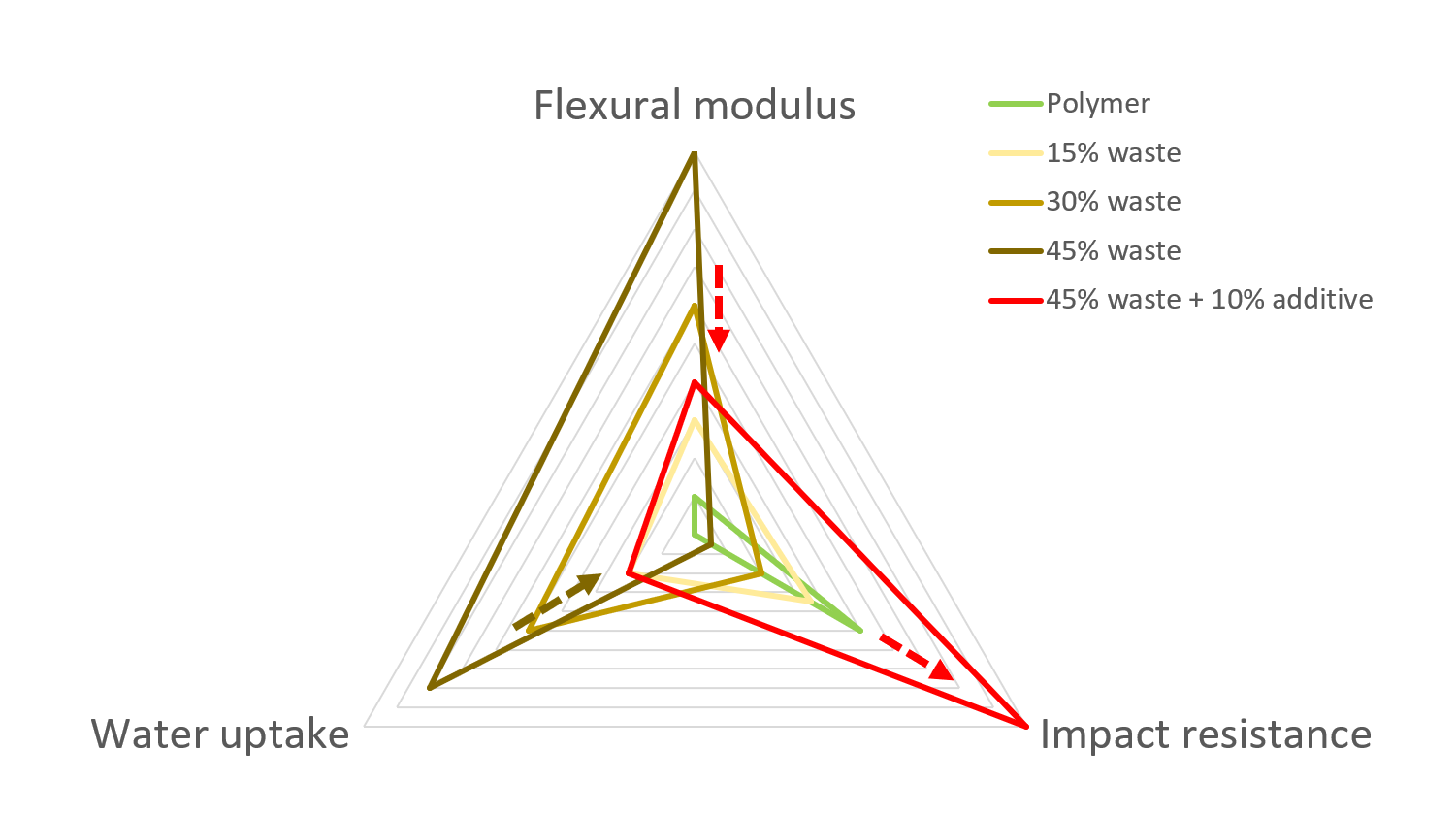

The introduction of household organic waste into a polymer via co-rotating twin-screw extrusion allows fine dispersion of the waste within the polymer. However, the resulting materials exhibit mechanical properties lower than those of the polymer (reduced impact strength, increased flexural modulus). This loss of properties is more pronounced as the content of incorporated waste increases.

By adding commercially available additives, high levels of organic waste can be incorporated while maintaining or improving the properties of the base polymer.

Composites produced through these additive strategies exhibit Melt Flow Index (MFI) values compatible with standard shaping/processing methods (injection molding and extrusion). Furthermore, the water sensitivity of these composites (water absorption or leaching of compounds) is very limited, opening possibilities for outdoor applications (decking, construction, containers, fences, furniture, decoration) with mechanical properties (e.g., impact resistance) superior to those of conventional polymers.

Solution

Fine dispersion of organic waste (up to 45%) in a polyolefin-type polymer matrix, using co-rotating twin-screw extrusion (with a specific screw profile) in the presence of a carefully selected additive (10 wt.% with appropriate physical and chemical properties), enables the production of a material suitable for outdoor applications (decking, construction, containers, fences, furniture, decoration) with mechanical properties (e.g., impact resistance) superior to conventional polymers. Incorporating 45% organic waste could also reduce the production cost compared to using the base polymer.