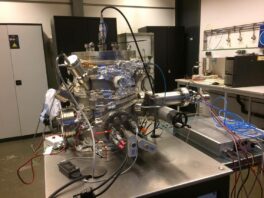

GLAD chamber

This chamber combines magnetron sputtering with GLAD (glancing angle deposition), i.e. it has a mobile substrate following two axes of rotation: inclination and rotation of the substrate. Possibility to obtain very porous and nanostructured films in inclined columns, vertical columns, zigzags, helixes. Possibility to crystallize the films in situ. Ideal for solar cell and photocatalysis applications that require thin films with a large specific surface area. An ion implanter is also connected to this chamber in order to modify the surface and the chemical composition of the nanostructured films by doping. Static or glancing angle magnetron sputtering and ion implantation can thus be coupled on this equipment.

Advantages

- Possibility to combine, in situ, static or glancing angle magnetron sputtering with ion implantation, with a temperature up to 500°C during treatments.