HI-ECOWIRE

- Start of the project : 01-04-20

- End of project : 30-09-23

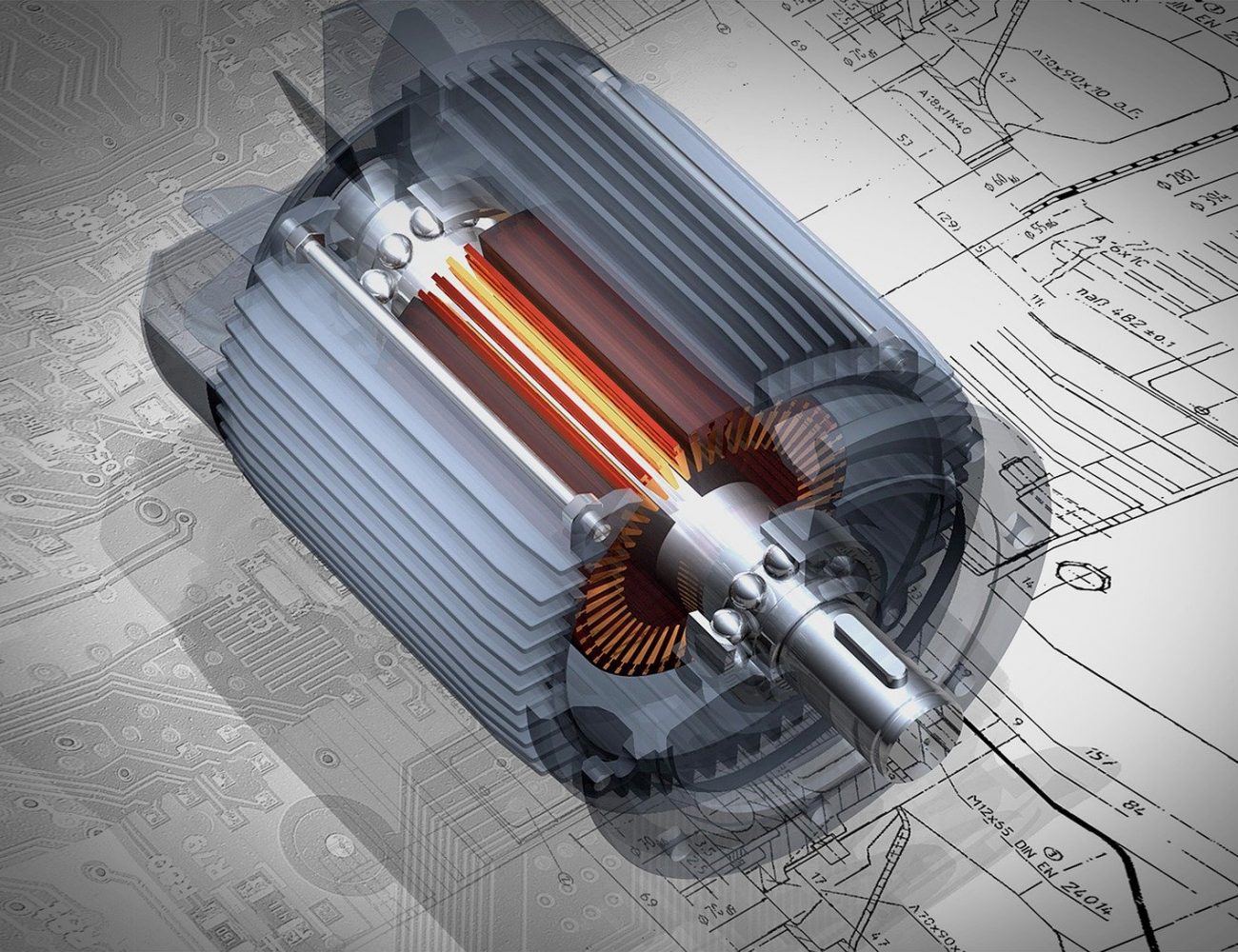

Magnet copper wire (annual production of 120,000 tons in North West Europe – NWE) is used for transformers and electric motors.

Technologies and materials are increasingly faced with growing environmental, productivity and competitiveness challenges, requiring a complete overhaul of their production methods. The HI-ECOWIRE project thus aims to develop a more sustainable and competitive production process with two main technical objectives:

- Improve the energy performance and efficiency of electric motors by 20-30% compared to the current situation by increasing the thermal class from 240°C to 280/300°C ;

- Replace the current varnish with a layer of polymers with superior thermal and dielectric performance.

This replacement should lead to a 90% reduction in the use of solvents. Current technology uses 12,000 tons/year of varnishes with toxic solvents that have to be burned with high energy consumption during transport, storage and management. In addition to the resulting massive CO2 and NOX emissions, the handling of these varnishes is confronted with the safety problems limiting the industrial activity of producing magnet wire. Replacing solvent-based varnishes with a polymer extrusion process would not only help to reduce solvent consumption and VOC emissions, but would also help to create industrial activities in areas where this is currently not possible due to the associated safety problems.

The project is based on an international consortium (SMEs, industries, research centres and universities) which aims to strengthen European competitiveness in the transport (aeronautics, automotive) and energy production (wind turbines) sectors while reducing the carbon footprint and the use of CMR solvents. Based on solutions developed at laboratory scale, the project will optimize new products and processes and validate them on an industrial scale. Constant interaction with industrial actors inside and outside the consortium, based on strong communication activities, will be the key to the success of the future technological transition proposed in HI-ECOWIRE. Associated partners – clusters, associations and agencies – will contribute to the communication, dissemination and diffusion of results and technologies that will enable the industries involved to have access to them.

HI-ECOWIRE is a 42-month Interreg NWE project. It is coordinated by Materia Nova and has 11 partners from France, Belgium, Germany, Ireland and Italy. The objective is to develop a competitive and sustainable magnet copper wire.

Objectives and missions of Materia Nova

As the main partner, Materia Nova will develop :

- Sol-gels as a polymer bonding base for enamelled copper wire.

- Extruded composite polymers for enamelled copper wire.

- An LCA (Life Cycle Assessment).