REVMAGWIRE

- Start of the project : 01-07-19

- End of project : 30-06-22

Magnet copper wire (annual production of 100,000 tons in Northern Europe) is used for transformers and electric motors. REVMAGWIRE aims to develop a sustainable and competitive production process with the objective of improving the energy performance and efficiency of electric motors by 20% to 30% by increasing the thermal class from 240°C to 280°/300°C. Current technology uses 10,000 tons of varnish/year with toxic solvents that must be burnt with high energy consumption during transport, storage and management. The massive emissions of CO2 and associated NOX give rise to safety problems limiting this industrial activity.

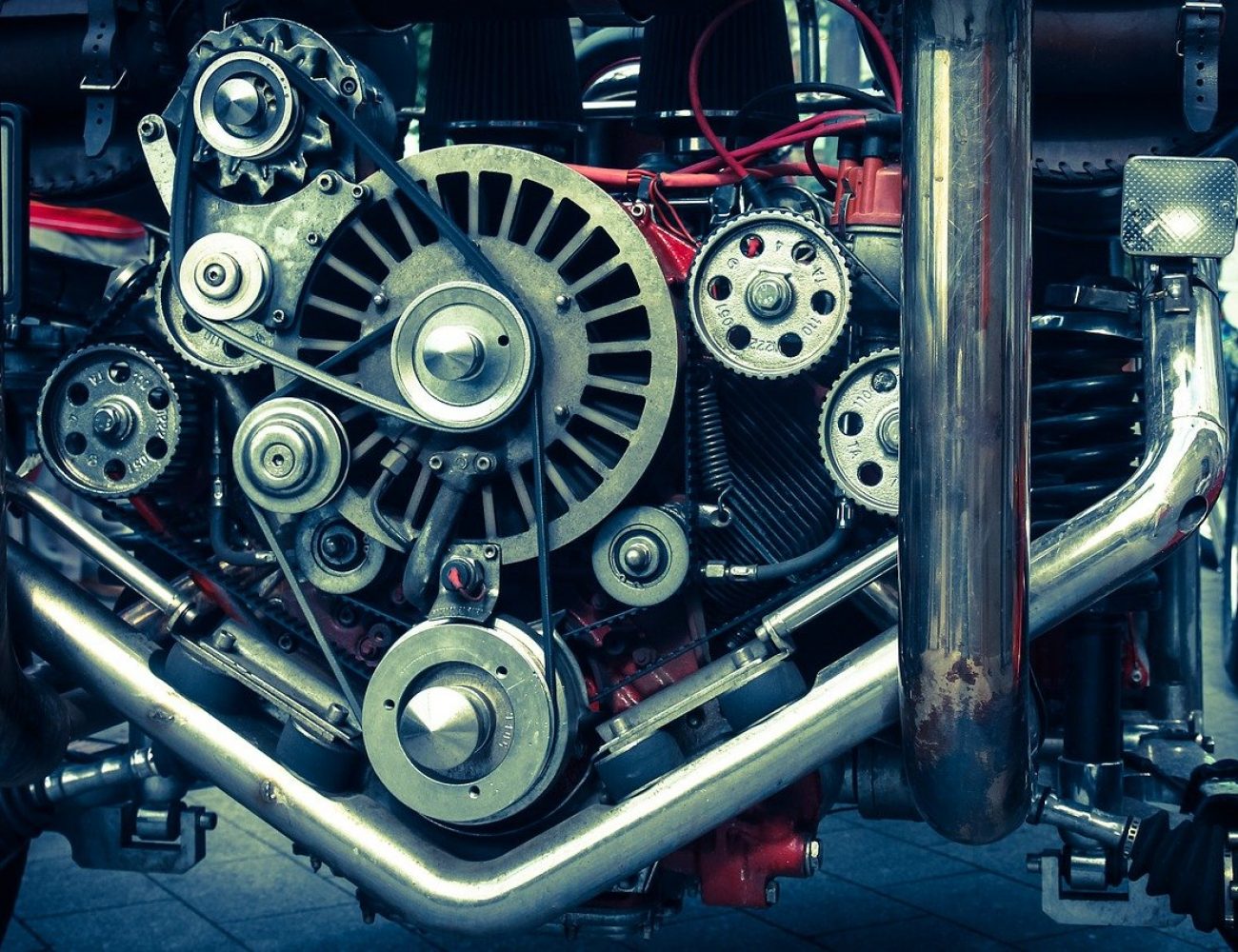

The main objective of the project is to develop a new complete solution for insulated copper wires for electrical engineering to be used in high temperature environments (280°C) and can be used in engines belonging to different industries (automotive, aeronautics, electronics...).

Objectives and missions of Materia Nova

Hybrid sol-gel coating formulation to be used as an enamel for high temperature resistant copper wire in addition to having the other properties required of insulated wire.

Participation in the development of the application process.

Evaluation of the environmental impact.