NIPU (Non Isocyanate PolyUrethanes)

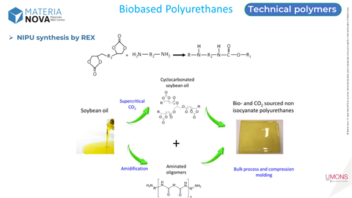

Thanks to research projects carried out at Materia Nova, new bio-based, biodegradable and non-toxic alternatives can be considered, such as NIPU: Non Isocyanate PolyUrethanes.

The chemistry is based on the action between amines and non-toxic cyclo carbonates. In addition, we focus on raw materials entirely biosourced and more particularly on chemical reagents obtained from vegetable oils (rapeseed, soybean, flax ...). Finally, the process incorporates CO2 during the cyclo carbonation process, thus reducing the carbon footprint.

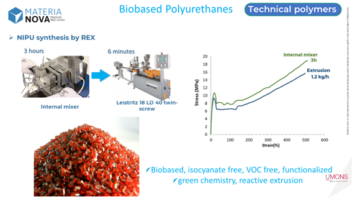

Materia Nova also focuses on green, continuous processes without organic solvents. Instead of carrying out the synthesis in a conventional reactor in a solvated environment, the new reactive extrusion processes allow for continuous polymerization without polluting solvents. The optimization of the extrusion process, of the screw profile and of the temperatures allows to increase considerably the polymerization kinetics and to obtain extruded polymer pellets in a few minutes.

Our strengths:

- Materia Nova has a fleet of extruders adapted to reactive extrusion, which allows it to scale up progressively to carry out grafting, chain extension or polymerization reactions, on a few tens of grams, hundreds of grams to a few kilograms. These extruders are equipped with accessories allowing the dosing of different reagents in liquid or powder form.

- Thanks to its range of analyses and structural, thermal, morphological, mechanical, biodegradation, bio-resorption and fire characterizations, Materia Nova can cover the entire development chain for composites with one or more properties.