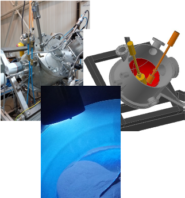

Rotating barrel system

The rotating barrel system technology developed by Materia Nova and IONICS consists of vacuum plasma deposition capable of coating powders (ranging in size from microns to several millimeters), beads or small bulk parts. This so-called “cold” technology has the advantage of being able to treat any type of substrate that cannot heat up to more than 50°C (metals, polymers, ceramics).

It also makes it possible to deposit materials with very varied chemical compositions such as metals and their ceramic compounds (oxides, nitrides, carbides, etc.) but also polymers. The deposits made range from a few tens of nanometers to micrometers.

The composition of the deposit and therefore of the powder after treatment can be finely adjusted in order to adjust the composition of the powder to the desire of the end consumer. Furthermore, if it is possible to produce “nanostructures” in order to optimize the specific surface area of the particles, it is also possible to produce a deposit perfectly covering the surface of each grain constituting the powder (formation of a “core- shell).

The applications of this technology are diverse in areas such as technical adhesives (conductive for example), catalysis, composite materials, sintering, thermal spraying, additive manufacturing, etc.

The equipment available at Materia Nova allows you to carry out:

1/ experimental productions wit ABBEADS I and II equipment: Treatment volume: 0.1-0.5 liters; Powders: 0.5 to 500µm; Small parts and beads: mm to cm; 1 or 2 cathodes; RF coil; All types of coatings (nitrides, carbides, etc.); Functionalization, Oxidation/reduction

2/ small series production with Plameco equipment: Treatment volume: 5 liters, Powders: 0.5 to 500µm; Small parts and beads: mm to cm; 1 or 2 cathodes; RF coil; All types of coatings (nitrides, carbides, etc.); Functionalization, Oxidation/reduction