Evaluation of the efficiency of the plasma torch cleaning

Question

Surface finish is one of the most important parameters for ensuring the adhesion of coatings, whether they are deposited using dry processes (PVD, PEVCD, etc.) or wet processes (paint, varnish, sol-gel, etc.).

How to efficiently remove pollution from surface whatever its topography? How to check the result of a cleaning treatment?

Expertise

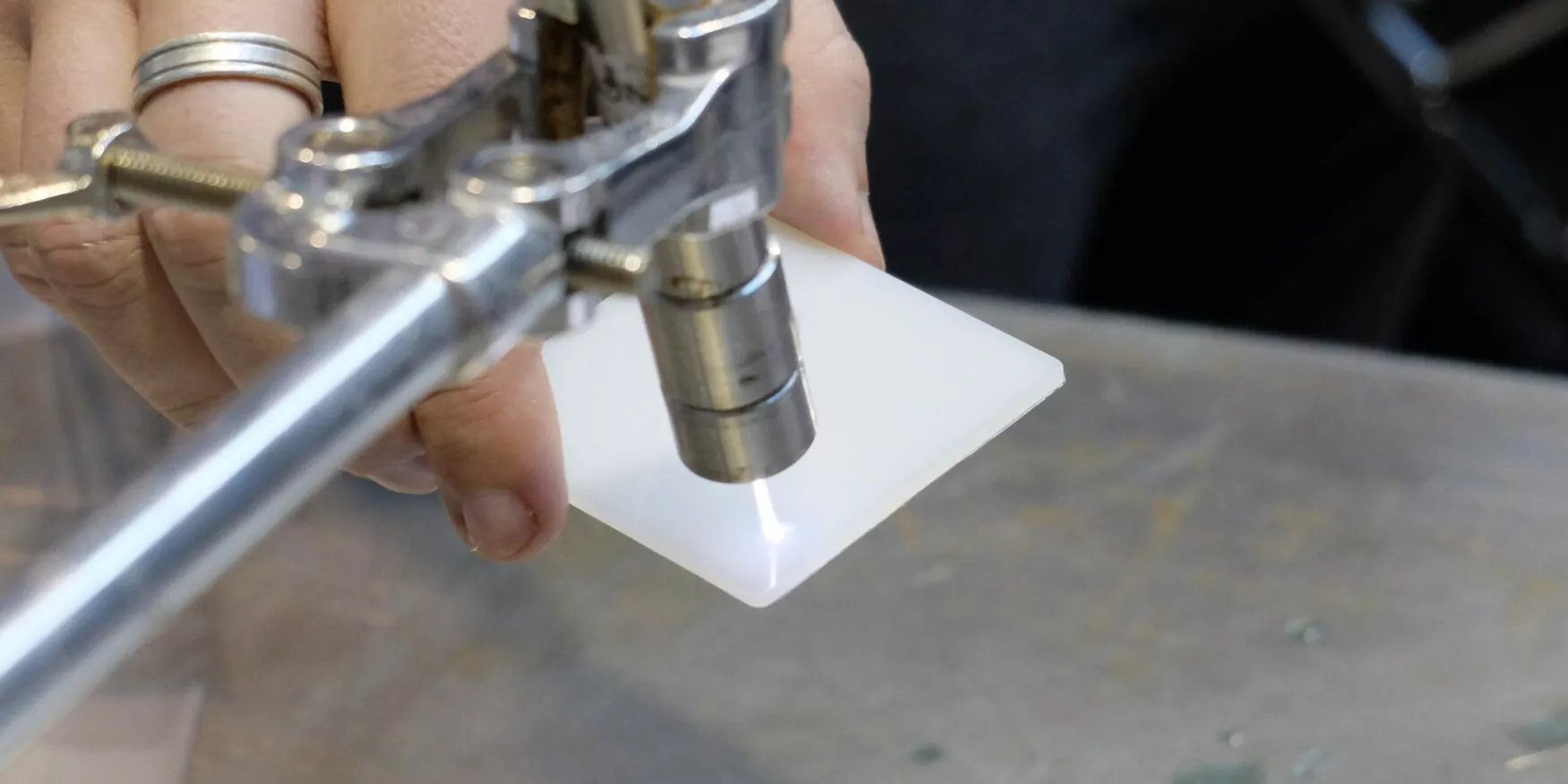

In collaboration with IONICS, Materia Nova has developed microwave plasma torches for optimum surface preparation prior to coating. The combined action of radicals and charged species in the plasma removes organic pollution from the surface.

To check surface cleanliness, Materia Nova uses techniques such as XPS or ToF-SIMS to measure the residual organic fraction on the surface of materials (determination of carbon content).

In this case, torch treatment is performed prior to metallization of a non-smooth copper surface. Before cleaning, Scanning Electron Microscopy (SEM) reveals the presence of organic impurities. The improved surface finish is clearly visible in the images taken after plasma torch treatment.

For even greater precision, the organic residue content is estimated using XPS (X-ray photoelectron spectrophotometry), which allow quantification of carbon on the surface with an accuracy of the order of 0.1% at. This technique, which probes surface chemistry over a thickness of around ten nanometers, can detect the presence of very small organic residues undetectable by SEM-EDX (energy dispersive X-ray spectroscopy). Indeed, our experience in coating deposition shows that a few nanometers of organic residue can compromise the adhesion of a coating.

In this case, a comparison of carbon content before and after treatment shows that organic contamination decreases considerably after plasma torch cleaning.

Solution

Scanning Electron Microscopy combined with XPS analysis can be used to visualize and quantify residual carbon content on a surface.

Plasma torch treatment is highly effective for cleaning even irregular surfaces contaminated by organic compounds. The surface condition is then optimal to ensure good adhesion of the coatings to be applied.

In more tricky cases, ToF-SIMS can be used to check surface cleanliness with greater sensitivity (in the ppm range), and to identify the nature of organic contaminants such as fatty acids or mineral oils.