Cleaning and surface preparation

Ensuring the adhesion of material coatings is fundamental for many industrial processes: painting, varnishing, gluing, metallization of plastics, metal coatings, multi-layers of materials. To guarantee this adhesion, the surface covered must be free of pollutants of all kinds (organic decontamination and decontamination) and properly prepared.

The preparation of the industrial surface is carried out by various separate or combined processes: chemical (cleaning, degreasing, oxidation), mechanical (pickling, abrasion), thermal or physical and must fit the subsequent coating process, whether wet (chemical or electrochemical baths...) or dry (thermal evaporation, cathodic sputtering, plasma, laser recharging...).

Our strengths

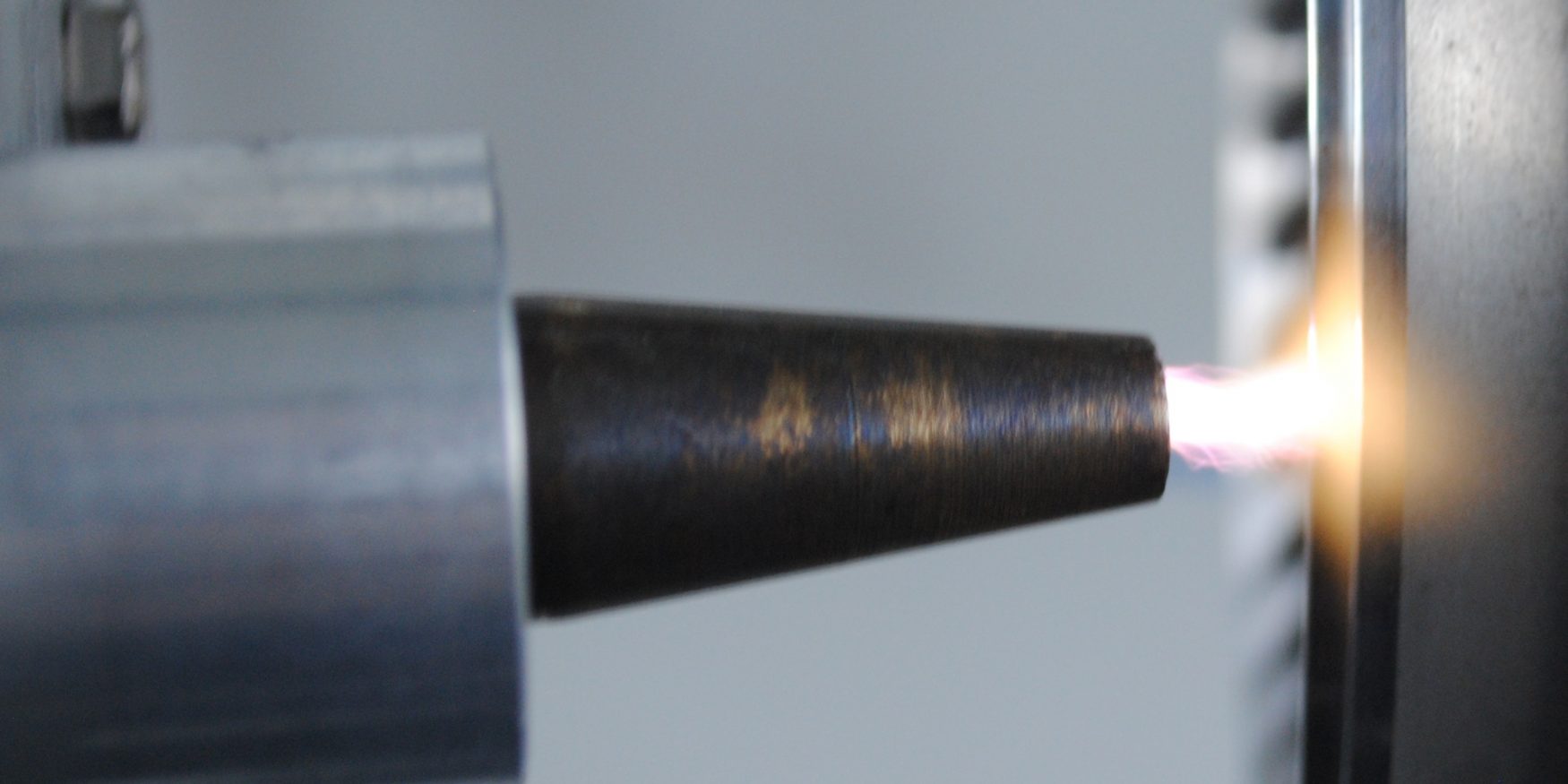

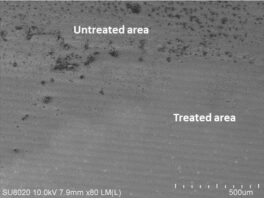

- Cleaning and decontamination approaches fitted to surfaces: UV/ozone, atmospheric plasma systems, heat treatment, etching and surface chemistry, CO2 snow jet, plasma torches.

- Controlling the wettability of surfaces or their chemical affinity.

- Dry surface decontamination, destruction of biological organisms on the surface of materials allowing dry and cold sterilization.

- Extensive offer in surface characterization (XPS, SIMS, SEM, raman, FTIR) to qualify the preparation or cleaning.