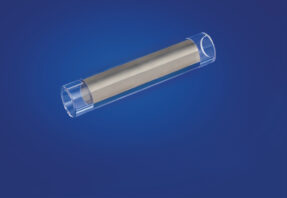

Surface (metallic and plastic) metallization

The metallization process consists of covering a surface to improve the electrical and/or thermal conduction properties, reinforce the mechanical or chemical potentials and also give an attractive and luxurious aesthetic appearance.

The increasing use of plastics in the transport sector and in particular for exterior parts and interior accessories responds to the need to reduce vehicle weight and improve energy efficiency, while complying with the strictest regulations in greenhouse gas emissions and the demand for environmentally friendly products. The hydrophobic nature of some of these polymers does not allow good adhesion of the coating to its surface.

Materia Nova has a large number of preparation processes, implementations and finishing operations allowing metallization on a wide range of surfaces, including non-conductive surfaces such as polymers and ceramics.

Our strengths

- Expertise in electrochemically produced coatings.

- Expertise in coatings obtained by dry process under vacuum (PVD) or at atmospheric pressure (plasma torch).

- Combination of processes for high-performance layer development.

- Adaptation of the deposition method to the geometry of the parts (3D on attachment or loose, hollow object).

- Expertise in providing additional functionality to metal cladding.