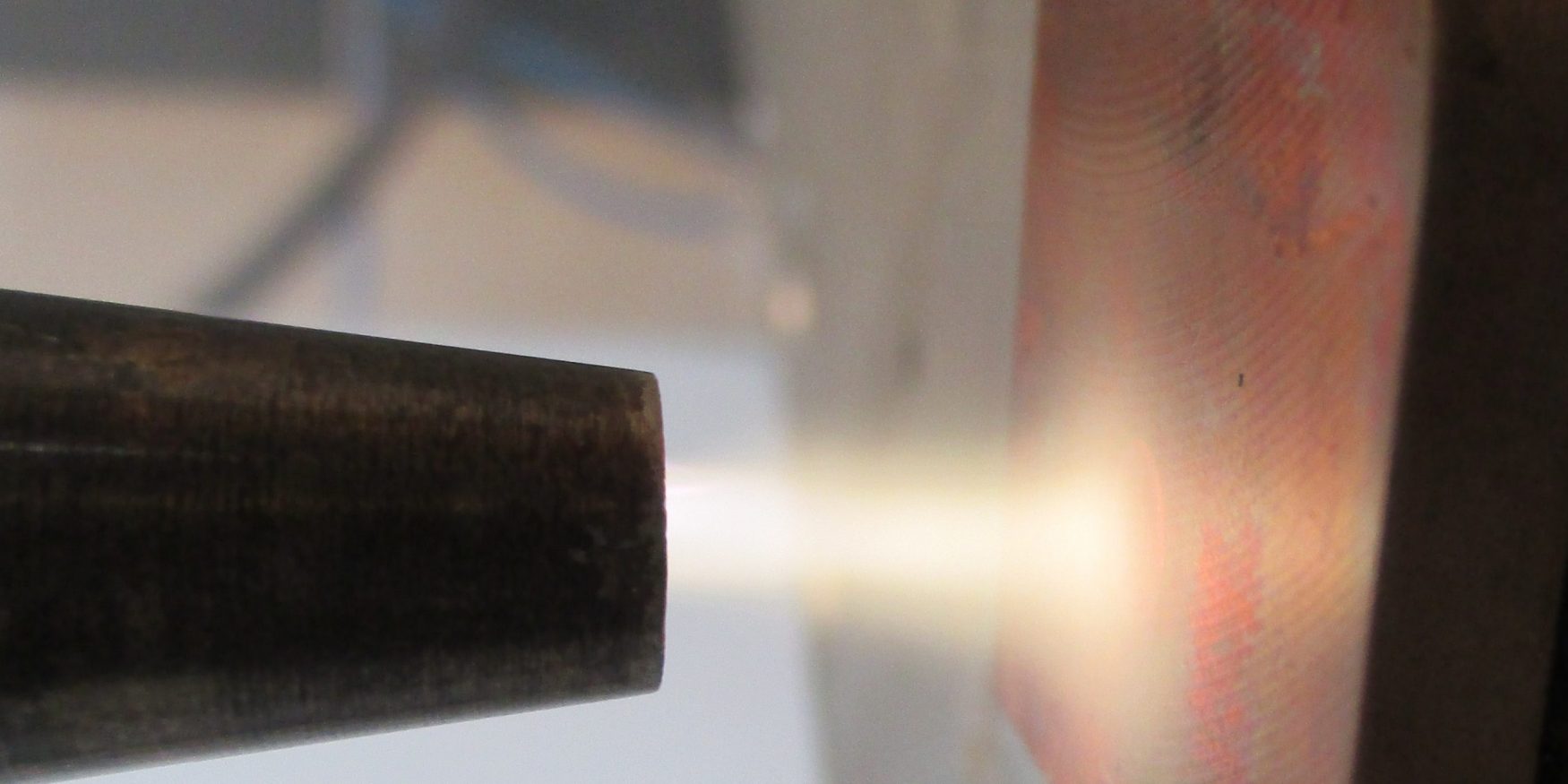

Cleaning with atmospheric plasma torch

Materia Nova developed in collaboration with IONICS microwave plasma torches, which generate a plasma outside the torch in direct contact with the substrate to be treated.

This gives the technology several advantages over conventional torches:

- Surface etching using ions and electrons for cleaning and surface preparation (prior to coating).

- Direct deposition of materials at atmospheric pressure from their powders.

- Deposition of materials from chemical precursors.

- Lower operating costs (gas, energy).

The combined action of plasma radicals and charged species eliminates surface organic pollution (creation of oxygen radicals).

In parallel with traditional torches, Materia Nova is developing and promoting the use of a new microwave plasma torch system enabling :

- More effective cleaning (dry air only / faster / short exposure time) of surfaces by electron and ion bombardment. These methods are now also used to destroy biological organisms on the surface of materials, enabling dry and cold sterilization. This method can also be used to eliminate surface organic pollution (creation of oxygen radicals), as well as to functionalize surfaces by grafting various chemical functions.

- modify the surface energy of even highly stable materials such as fluoropolymers, to control surface wettability or chemical affinity

- Reduce carrier gas consumption, noise and energy consumption.

Our strengths:

- Customized system development , deposition from precursor or directly by powder fusion.

- Close collaboration with IONICS, which builds, sells or rents this customized equipment.