Hydrogen production

The European Union wants to make “clean” hydrogen a key element of the energy mix by 2050.

Hydrogen can be used as a feedstock, fuel or energy carrier and storage solution. It has many possible applications in the industrial, transport, electricity and construction sectors. Most importantly, its use does not cause CO2 emissions and does not pollute the atmosphere. Hydrogen is therefore an important element of the solution to achieve the objective defined by the European Green Deal of climate neutrality by 2050.

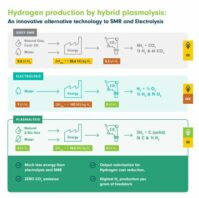

Hybrid Methane Plasmalysis is a new technological pathway that enables the simultaneous production of hydrogen and solid carbon with a significantly reduced carbon footprint.

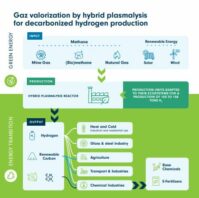

This patented breakthrough technology makes it possible to convert various methane sources—such as mine gas, biomethane, coalbed methane, and natural gas—into two high-value co-products: hydrogen and solid carbon.

A laboratory-scale demonstration pilot is currently being finalized at Materia Nova. It will produce up to 3.3 kg/h of hydrogen and 10 kg/h of solid carbon in a modular and scalable installation, designed to integrate different plasma reactor configurations.

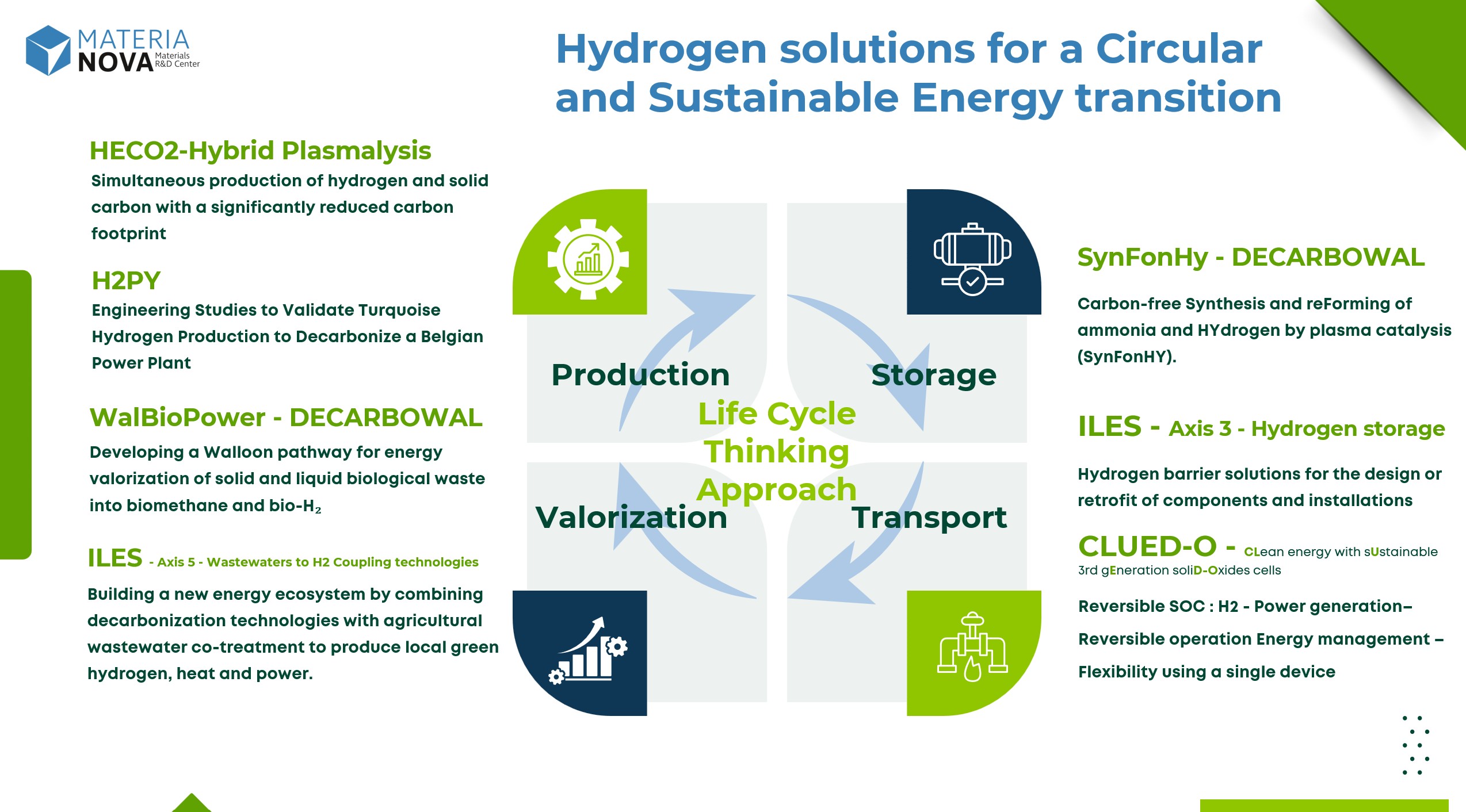

The illustration below presents some of the projects and Materia Nova’s integrated vision to support the development of a sustainable, circular hydrogen value chain that is consistent with current environmental requirements. This vision is structured around four essential pillars of the hydrogen life cycle.

Our Strengths

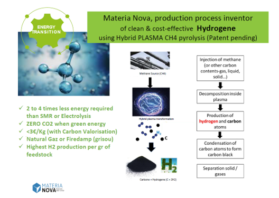

- Materia Nova has been investing for many years in the research and development of clean processes for the production of green hydrogen. In October 2020, it filed a patent on the optimization of the process and equipment for cracking methane (mine gas and biogas) using the HYBRID PLASMALYSIS process which produces so-called “turquoise” hydrogen and carbon black. (CH4=> C + H2).

- This new innovative process makes it possible, compared to electrolysis and SMR (steam methane reforming) processes, to reduce energy consumption by 2 to 4 times. It does not generate CO2 emissions and, thanks to carbon recovery, its cost price is less than €3/kg H2. This patented manufacturing process allows higher hydrogen production (per gram of raw material) and reduces the risk of explosion (vs. O2/H2 mixture). It does not require pure water and does not compete with the use of agricultural land.

- Materia Nova also invests in other green hydrogen production processes such as plasma treatment of biogas, urea electrolysis, bioprocesses (Microbial PEM (Biofuel/H2) but also in related innovations such as new materials for storage and transport and leak detection sensors.

- Plasmas are recognized as an alternative to the thermal cracking process because they can operate at lower temperatures. It allows the valorization of H2S by directly producing hydrogen and solid sulfur, losing a minimum of energy injected in thermal form (not useful for conversion) and without CO2 emissions (considering that electricity used is CO2 neutral). H2S2H2: H2S => H2+S