Bioplastics

Whether they come from renewable or fossil sources, bioplastics may or may not be biodegradable. Their end-of-life does not depend on their origin. These materials can be natural or synthetic, produced by chemical or biological processes. The generation of biosourced plastics, or bioplastics, from plant materials has opened the way to a sustainable alternative to the problem of using fossil resources.

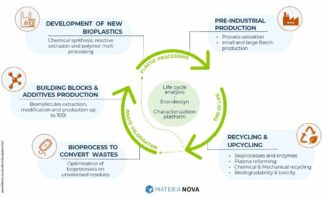

Through its various development projects, Materia Nova has acquired solid expertise in the innovative design and chemical synthesis of biomaterials and bioplastics: design, modification, synthesis, polymerisation, functionalisation and compatibilisation.

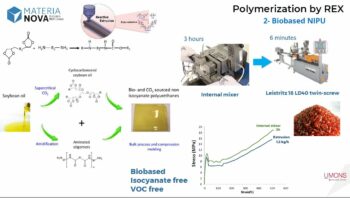

NIPU: Non Isocyanate PolyUrethanes

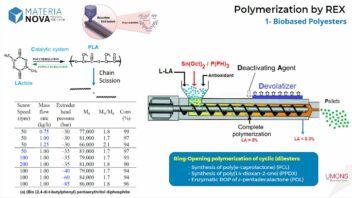

Polyesters: ring-opening polymerisation of cyclic (di)esters: synthesis of poly(e-caprolactone) (PCL), synthesis of poly(1,4-dioxan-2-one) (PPDX), enzymatic ROP of ɛ-pentadecalactone (PDL).

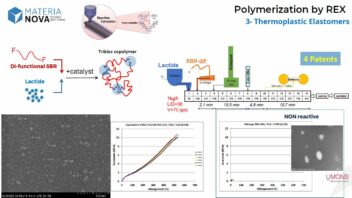

Elastomeric thermoplastics:

- Synthesis with enzymes by reactive extrusion and study of PLA degradation by enzyme,

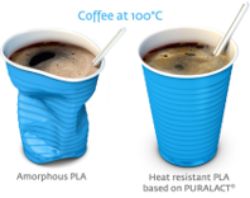

- Improvement of PLA properties (thermal resistance, high resistance to tearing in the transverse direction, mechanical resistance in the longitudinal direction, etc.),

- Integration of nanofillers to modify and add properties of interest (anti-microbial, anti-oxidant, conductive, ethylene capture, etc.) to PLA while preserving its physico-chemical properties (mechanical, etc.),

- Development of other bio-based materials: PBS, PBAT and PHA

- Improve their "elastic" properties to make them less brittle,

- Modification to make them easier to process and adapt their properties to end applications (MFI/MFR of PP, water resistance like starch or cellulose, fire resistance, etc.).

- Compatibility (PLA/ABS and PLA/PBS)

Our strengths

- Materia Nova is able to cover all stages of development of these biomaterials. From the extraction and development of bio-building blocks to the development of the biopolymer, its chemical modification and formulation.

- Platform for chemical, physicochemical characterizaton, structural, thermal and mechanical properties.

- Biotechnology laboratory for the production and extraction of biomolecules (precursors and/or additives).

- Equipment adapted to the modification of polymers by reactive process in reactors and extruders.

- We modify biopolymers to facilitate their transformation and adapt their properties to the final applications.